Electrical

adjustments.

Adjustments are required after

replacing circuit components and certain mechanical parts.

It is important to

perform these adjustments only after all repairs and replacements have been

completed. Also, do not attempt these

adjustments unless you do not have proper equipment is available.

To do the adjustments, you need a

service remote control. There is no service remote control, to buy anywhere. Service remote

control can be prepared from the supplied user remote control.

See how to prepare a service

remote control, from the user remote control.

How

to make the service remote control unit.

Cut the marked portion shown below illustration, of your user remote control. There is a service button underneath. You can get access to Service Button.

Pressing it, can see the service mode screen.

Be carefull to do adjustments in service mode.

Service

mode:

1. Use the service remote control unit.

2. Turn the power on.

3. Press the service button on the service remote control unit as shown in fig.

Purity

check mode. Up1. Use the service remote control unit.

2. Turn the power on.

3. Press the service button on the service remote control unit as shown in fig.

This mode cycles through full-screen displays of red, green, blue, and white to

check for non-active pixels.

1. Enter the service mode.

2. Each time pressing [7] button on the service remote control unit, the display changes as follows.

1. Enter the service mode.

2. Each time pressing [7] button on the service remote control unit, the display changes as follows.

Auto

calibration [component]

Purpose: to bring the color adjustment of each component into standard alignment.

Symptom of maladjustment: if this adjustment is incorrect, component signals do not reproduce the corresponding color.

1. Input 1080i 100% color bar signal.

2. Enter the service mode.

3. To enter the auto calibration adjustment mode, press [6] button on service the remote control unit.

4. To start auto adjustment, press [1] button on the service remote control unit.

- In the auto adjustment mode, “please wait” appears on the screen.

- Upon completion, “ok” appears on the screen.

Purpose: to bring the color adjustment of each component into standard alignment.

Symptom of maladjustment: if this adjustment is incorrect, component signals do not reproduce the corresponding color.

1. Input 1080i 100% color bar signal.

2. Enter the service mode.

3. To enter the auto calibration adjustment mode, press [6] button on service the remote control unit.

4. To start auto adjustment, press [1] button on the service remote control unit.

- In the auto adjustment mode, “please wait” appears on the screen.

- Upon completion, “ok” appears on the screen.

Auto

calibration [DTV]

purpose: to bring the color adjustment of DTV into standard alignment.

Symptom of maladjustment: if this adjustment is incorrect, DTV signals do not reproduce the corresponding color.

1. Enter the service mode.

2. To enter the auto calibration adjustment mode, press [6] button on the service remote control unit.

3. To start auto adjustment, press [2] button on the service remote control unit.

- In the auto adjustment mode, “please wait” appears on the screen.

- Upon completion, “ok” appears on the screen.

purpose: to bring the color adjustment of DTV into standard alignment.

Symptom of maladjustment: if this adjustment is incorrect, DTV signals do not reproduce the corresponding color.

1. Enter the service mode.

2. To enter the auto calibration adjustment mode, press [6] button on the service remote control unit.

3. To start auto adjustment, press [2] button on the service remote control unit.

- In the auto adjustment mode, “please wait” appears on the screen.

- Upon completion, “ok” appears on the screen.

Auto

calibration [PC]

purpose: to bring the color adjustment of pc into standard alignment.

Symptom of maladjustment: if this adjustment is incorrect, pc signals do not reproduce the corresponding color.

1. Input XGA 100% white signal.

2. Enter the service mode.

3. To enter the auto calibration adjustment mode, press [6] button on service the remote control unit.

4. To start auto adjustment, press [3] button on the service remote control unit.

- In the auto adjustment mode, “please wait” appears on the screen.

- Upon completion, “ok” appears on the screen.

purpose: to bring the color adjustment of pc into standard alignment.

Symptom of maladjustment: if this adjustment is incorrect, pc signals do not reproduce the corresponding color.

1. Input XGA 100% white signal.

2. Enter the service mode.

3. To enter the auto calibration adjustment mode, press [6] button on service the remote control unit.

4. To start auto adjustment, press [3] button on the service remote control unit.

- In the auto adjustment mode, “please wait” appears on the screen.

- Upon completion, “ok” appears on the screen.

The

following adjustment normally is not attempted in the field. Only when

replacing the LCD panel then adjust as a preparation.

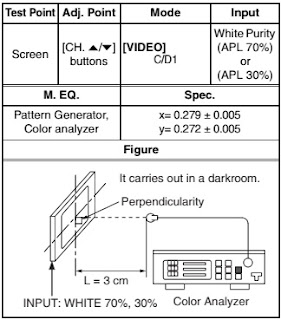

White

balance adjustment [video]

purpose: to mix red, green and blue beams correctly for pure white.

Symptom of maladjustment: white becomes bluish or reddish.

purpose: to mix red, green and blue beams correctly for pure white.

Symptom of maladjustment: white becomes bluish or reddish.

1. Operate the unit for more than 20

minutes.

2. Input the white purity

2. Input the white purity

3. Set the color analyzer to the

chroma mode and bring the optical receptor to the center on the lcd-panel

surface after zero point calibration as shown below.

Note: the optical receptor must be set perpendicularly to the LCD panel surface.

Note: the optical receptor must be set perpendicularly to the LCD panel surface.

4. Enter the service mode. press

[vol. dn] button on the service remote control unit and select “c/d1” mode.

3. Set the color analyzer to the

chroma mode and bring the optical receptor to the center on the lcd-panel

surface after zero point calibration as shown above.

Note: the optical receptor must be set perpendicularly to the LCD Panel surface.

4. Enter the service mode. Press [vol.dn] button on the service remote control unit and select “c/d2” mode.

5. [Cutoff]

press [1] button to select “cor” for red cutoff adjustment. Press [3] button to select “cob” for blue cutoff adjustment.

[Drive]

press [4] button to select “dr” for red drive adjustment. Press [6] button to select “db” for blue drive adjustment.

6. In each color mode, press [ch.up/dn] buttons to adjust the values of color.

7. Adjust cutoff and drive so that the color temperature becomes 11000k (x= 0.279 / y= 0.272 ±0.005)

Note: the optical receptor must be set perpendicularly to the LCD Panel surface.

4. Enter the service mode. Press [vol.dn] button on the service remote control unit and select “c/d2” mode.

5. [Cutoff]

press [1] button to select “cor” for red cutoff adjustment. Press [3] button to select “cob” for blue cutoff adjustment.

[Drive]

press [4] button to select “dr” for red drive adjustment. Press [6] button to select “db” for blue drive adjustment.

6. In each color mode, press [ch.up/dn] buttons to adjust the values of color.

7. Adjust cutoff and drive so that the color temperature becomes 11000k (x= 0.279 / y= 0.272 ±0.005)

White

balance adjustment [component / DTV]

purpose: to mix red, green and blue beams correctly for pure white.

Symptom of maladjustment: white becomes bluish or reddish.

purpose: to mix red, green and blue beams correctly for pure white.

Symptom of maladjustment: white becomes bluish or reddish.

1. Operate the unit for more than 20

minutes.

2. Input the white purity. as

described above.

3. Set the color analyzer to the

chroma mode and bring the optical receptor to the center on the lcd-panel

surface after zero point calibration as shown below.

Note: the optical receptor must be set perpendicularly to the lcd panel surface.

4. Enter the service mode. press [vol.dn] button on the service remote control unit and select “c/d2” mode.

5. [cutoff]

press [1] button to select “cor” for red cutoff adjustment. Press [3] button to select “cob” for blue cutoff adjustment.

[drive]

press [4] button to select “dr” for red drive. press [6] button to select “db” for blue drive adjustment.

6. in each color mode, press [ch.up/dn] buttons to adjust the values of color.

7. Adjust cutoff and drive so that the color temperature becomes 11000k (x= 0.279 / y= 0.272 ±0.005).

Note: the optical receptor must be set perpendicularly to the lcd panel surface.

4. Enter the service mode. press [vol.dn] button on the service remote control unit and select “c/d2” mode.

5. [cutoff]

press [1] button to select “cor” for red cutoff adjustment. Press [3] button to select “cob” for blue cutoff adjustment.

[drive]

press [4] button to select “dr” for red drive. press [6] button to select “db” for blue drive adjustment.

6. in each color mode, press [ch.up/dn] buttons to adjust the values of color.

7. Adjust cutoff and drive so that the color temperature becomes 11000k (x= 0.279 / y= 0.272 ±0.005).

How

to initialize the lcd television

1. turn the power on.

2. To enter the service mode, press the service button on the service remote control unit.

1. turn the power on.

2. To enter the service mode, press the service button on the service remote control unit.

To cancel the

service mode, press [power] button on the service remote control unit.

3. Press [display] button on the service remote control unit to initialize the lcd television.

4. "ff" will appear in the upper left of the screen. "ff" color will change to red from white when initializing is complete.

3. Press [display] button on the service remote control unit to initialize the lcd television.

4. "ff" will appear in the upper left of the screen. "ff" color will change to red from white when initializing is complete.

Test equipment

required

1. DC voltmeter

2. NTSC pattern generator (color bar w/white window, red color, dot pattern, gray scale, monoscope, multi-burst)

3. Remote control unit

4. Color analyzer.

1. DC voltmeter

2. NTSC pattern generator (color bar w/white window, red color, dot pattern, gray scale, monoscope, multi-burst)

3. Remote control unit

4. Color analyzer.

Schematic

[full]