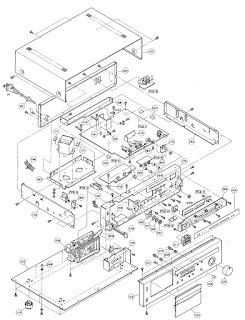

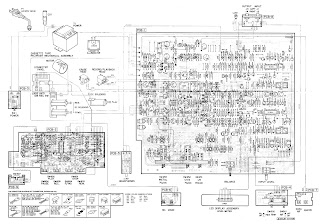

Exploded views of CD mechanism, tape deck, full circuit diagram and wiring diagram.

Wednesday, September 30, 2020

The Harman Kardon CD91 Circuit diagram, exploded view – Ultrawideband Linear Phase Cassette Deck

Monday, September 21, 2020

TCL 14F7NX56CLA NX56AP and NX56B AP How to enter the service mode, adjustments, SMPS schematic

Version Information: Version states by two Arabic Numbers,

which is separated by one dot, e.g. 1.2. The first number “1” means the version

of approved file, the second one ”2” means the version of draft.

The way to enter P-Mode

Method one

A) Switch on the TV set.

B) Press the “MENU” key on RC to show the “PICTURE” OSD

menu.

C) Move the cursor to “Contrast” item then press the “9”,

“7”, “3”, “5” key continuously on RC within 3 seconds then enter P-Mode. The

“P” letter will appear on the left low corner of the screen when enter P-Mode.

Also the “FACTORY HOTKEY” will be set to “ON (= 1)”.

Another method

Press the “RECALL” key on RC to enter P-mode directly.

Note:

1. This will be active only when the “FACTORY HOTKEY” had

set to “ON (= 1)”.

2. When the power on with “FACTORY HOTKEY” had set to “ON (=

1)”, the set will enter the P-Mode automatically.

Exit the P-Mode

Press the “RECALL” or “MENU” key on RC to exit the P-Mode.

Keys’ function on RC at the P-Mode

Use the RC to navigate in P-Mode:

Press “0” or “AT” key for screen voltage adjustment.

Press “1” to “8” and “FAV” key to select factory adjustment

page.

Press “9” key to switch the I2C bus off/on.

Press “▲▼” or “CH+ CH-”key

to select option.

Press “►◄” or “VOL+ VOL-”

key to adjust or select option.

Press “DISPLAY” key to display software version.

Press “MENU” key to close the factory menu or return to the

previous menu or exit the P-Mode.

Press “RECALL” key to enter or exit the P-Mode.

Note: All change in P-Mode will be saved in EEPROM

automatically.

B+ Voltages

1. All relevant connectors and modules must be connected and

inserted.

2. Main voltage is at 220VAC, 50Hz.(

voltage range:110VAC~240VAC,50Hz)

3. Connect a voltmeter to B+ (Cathode of D808 for NX56

chassis or cathode of D833 for NX56B chassis) and switch on the set.

4. Input Philips test pattern signal and standard mode.

5. Adjust VR801, it should as the value in below form B+

Voltage.

RF AGC alignment

Method 1

A. Connect the detector as shown below (Picture 3.2) to

collector of Q101.

B. Receive a grey scale signal with 70dBμV amplitude.

C. Enter P-Mode, press “6” key on RC to select “AGCT”.

D. Adjust AGCT item until the output of the detector becomes

0.8Vpp.

Method 2

A. Receive a grey scale signal with 60dBμV amplitude.

B. Enter P-Mode, press “6” key on RC to select “AGCT”.

C. Adjust the “AGCT” value until the hint display “AGC” just

change between “0” and “1”.

Screen and Focus adjustment

Note: Alignment below should be done after 15 minutes warm

up of TV.

1. Input cross hatch pattern signal to RF input.

2. Enter P-Mode.

2. Press “0” key on the RC and the screen will become a

horizontal line.

3. Adjust the “SCREEN” VR of the FBT until the horizontal

line can just be seen barely (minimum visible intensity).

4. Press “0” key again on the RC to exit the screen voltage

adjustment mode.

5. Adjust the “FCOUS” VR of the FBT until the vertical line

and horizontal line becomes Clear.

White Balance Adjustment

1. Input a black and white pattern to RF input.

2. Enter P-Mode, press key “3” to select white balance

adjustment menu.

3. Use the color analyzer to measure the black side of the

screen. Adjust the value of “RC”,”GC” and “BC” to set the reading of the color

analyzer to x=274, y=280. (11500 K).

4. Then measure the white side of the screen. Adjust the

value of “RD”, “GD” and “BD” to set the reading of the color analyzer to x=274,

y=280. (11500 K).

5. Repeat step 3&4 until you can get the correct reading

for both black and white sides.

Note:

A. The “SubBRI” and “SubCON” items are used to assistant the

white balance adjustment.

It is the same function as the user OSD menu “Brightness”

and “Contrast” items. You can adjust these items to get the expect intensity

when adjusting the white balance.

B. The “BLOR-Y”, “BLOG-Y” and “BLOB-Y” items are used for

the YUV white balance black level offset setup. When the TV white balance

adjustment is done, connect a black and white pattern to YUV input terminal.

Use the color analyzer to measure the black side of the screen. Adjust the

value of the “BLOR-Y”, “BLOG-Y” and “BLOB-Y” to set the reading of the color

analyzer to x=274, y=280.

Sub brightness adjustment

1. Input eight steps gray signal.

2. Press key “3” to enter sub-brightness adjustment.

3. At dynamic state, adjust “BRTC” until the secondary gray

bar just to be seen.

Picture Geometry adjustment: Vertical

geometry adjustment

1. Input a PAL crosshatch pattern signal to RF input.

2. Enter P-Mode, press key “1” to select vertical geometry

adjustment. (The OSD menu for this adjustment as below table 3.6.1. For NTSC

signal, the “-50” will be replaced with “-60”.)

3. Adjust the value of the corresponding item to make the

vertical geometry of the pattern look good.

4. Apply NTSC signal to adjust these value for NTSC vertical

geometry.

1. For NTSC signal, the “-50” will be replaced with “-60”.

2. For NTSC signal, only the “VCEN-60” and “VSIZE-60” items

need the adjustment, the other items use the same data as PAL signal.

3. On producing, please use the “AUTO OFFSET” (On page “2”)

function to easy the geometry adjustment of NTSC signal. When finished the PAL

signal geometry adjustment, press “2” key to enter page “2” to select “AUTO

OFFSET” item, press “►” key to active the automatic offset function. Then the

geometry adjustment of NTSC signal will finish automated. If the geometry of

NTSC signal is look good, you don’t need to adjust the geometry of NTSC signal

any more.

Horizontal geometry adjustment

1. Input a PAL crosshatch pattern signal to RF input.

2. Enter P-Mode, press key “2” to select horizontal geometry

adjustment. (The OSD menu for this adjustment as below table 3.6.2. For NTSC

signal, the “-50” will be replaced with “-60”.)

3. Adjust the value of the corresponding item to make the

horizontal geometry of the pattern look good.

4. Apply NTSC signal to adjust these value for NTSC

horizontal geometry.

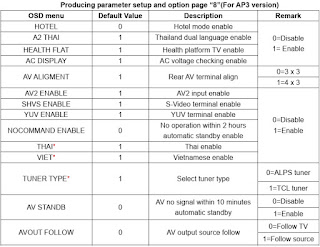

Producing parameter setup and

option

1. Enter P-Mode, press key “4” to select page “4”.Set the

corresponding item to require value.

1). Set the shopping status

When trigger the “SHOP INIT” item form “0” to “1”, the TV

will be put on selling status.

The TV status after shopping status:

“FACTORY HOTKEY” had set to “OFF”

B. Picture set to “Standard” status. (Brightness=50,

Contrast=50, Colour=50, White tone=Normal.)

C. Sound set normal.(Volume=30,Balance=50.)

3). Set the value for “POWER LOW” and “POWER HIGH”

A. Connect the main voltage at low threshold 95VAC/50Hz.

B. Select item “POWER LOW”.

C. Adjust the value until the hint display just change

between “AC: NORMAL” and “AC: LOW”.

D. Connect the main voltage at high threshold 255VAC/50Hz.

E. Select item “POWER HIGH.

F. Adjust the value until the hint display just change

between “AC: NORMAL” and “AC: HIGH”.

2. Enter P-Mode, press key “5” to select page “5”. Set the

corresponding item to require value. See below table for detailed description.

Description for AUTO OFFSET and

GET OFFSET

The “GET OFFSET” can use to make the EEPROM copy by PE

engineer. When the PAL and NTSC geometry adjustment had finished, trigger the

“GET OFFSET” from “0” to “1” to store the geometry offset datum between PAL and

NTSC in EEPROM.

On producing, these geometry offset datum can use to easy

the NTSC geometry adjustment. When finished the PAL geometry adjustment,

trigger the “AUTO OFFSET” from “0” to “1”, then the geometry adjustment of NTSC

signal will finish automated. If now the geometry of NTSC signal is look good,

it not needed to adjust the geometry of NTSC signal any more.

3. Enter P-Mode, press key “6” to select page “6”. Set the

corresponding item to require value. See below table.

4. Enter P-Mode, press key “7” to select page “7”. Set the

corresponding item to require value. See below table

Enter P-Mode, press key “8” to select page “8”. Set the

corresponding item to require value. See below table

Note: When change the Language or the tuner type, you must

AC restart the TV set to make it active

6. Enter P-Mode, press key “FAV” to select page “9”. Set the

corresponding item to required value.

Screen voltage (VG2) adjustment

with AKB function

1. Put the TV in AV source without input signal.

2. Enter P-Mode, press RC key "AT", there will

display

3. Adjust the "SCREEN" VR of the FBT until VG2

hint display (LOW/OK/HIGH) display "OK" stably.

4. Press “MENU” return to P-Mode.

Printed circuit board Foil Side

SMPS schematic

Horizontal and Vertical output schematic

Monday, September 7, 2020

LGD FHD LGP37C-12HPC EAY62788701 SMPS board schematic, connector voltages, test method

Power Supply Unit LGD : LGP37C-12HPC AC 100V to AC 240V Used in 37 inch LGE LCD TV Part code : LGD EAY62788701

80A

zero-peak max.

At cold start and any specified line, load, and temperature Conditions. The power supply efficiency should be more than 80% at the 90Vac maximum load condition, but it meet more than 85% excepted Inverter parts. Power Factor over than 0.9 at 90 – 264Vac & max load condition.

On

Condition: In a moment of Power-ON Signal activated, the current of 3.5V output

should be limited within 40mA(Max) at LCD TV condition for stability. [Do not turn “Power-ON” Signal on at the load

condition of 3.5V output, more than 40mA.]

*

Total regulation for each output circuit includes the results of input voltage variation,

load variation, warm-up drift and temperature change.

*

The following instruments shall be used for measuring ripple noise.

1.

Probe having impedance ratio of 1:1.

2.

Oscilloscope having frequency characteristic of 100MHz or more.

[Ripple

and noise are measured at the end of output cable which are added a 0.1uF

ceramic capacitor and 47uF electrolytic capacitor ( connected parallel ) . (

connected parallel )]

Burn-in

More

than 30 minutes at 45℃(±5℃), Normal input voltage.

AC

on/off must be test 1 time after burn-in.

80%

Load of specification.

Protection

*

This Power Supply has above-mentioned protections.

*

Short circuit protection between different output terminals is not considered.

*

Trip point for over voltage indicates the operating point when the output

voltage slowly increases.

*

The conditions of Over Current measurement

Multi

output [3.5V, 12V, 24V] is normal load state except an over current

measurement.

Sound Noise Characteristics.

PSU

Noise Specification

22.5

dB(a) / 20.u Pa 2.0E-5 Pa

(1/1

octave, A-weighting, to 1khz ~ 16khz Total overall)

Measure

Location: Anechoic Room

Measure

Condition: At a distance of 60cm mike

Full

white pattern, at AC 110V/220V

The

max specification

(Measure

3 points, at PSU centre and left & right on the side)

Connectors Usage and voltages

Test methods

Intermittent

Operation stability Test: The switching

regulator shall ON/OFF for 20,000 time at an Interval of 10 sec at maximum

load, after that electrical Characteristics shall be satisfied.

Low

temperature operation: The switching

regulator is left at the operating guarantee Minimum temperature for 2 hours

without applying electricity. After that

that power shall be turned on, and then the electrical Characteristics shall be

satisfied.

Low

temperature Storage test Leave At low temperature: The switching regulator is left at minimum

storage Temperature for 96 hours or more.

Then the switching regulator is left at a room temperature and humidity

for 1 hour or more, after that electrical characteristics shall be satisfied.

Heat

cycle storage test: Then the switching regulator is left at a room temperature

and humidity for 1 hour or more, after that electrical characteristics shall be

satisfied.

Heat

shock test: Heat shock test performed under following conditions without

applying electricity and then leave them at room temperature and humidity for 1

hour or more.

After

that, electrical characteristics shall be satisfied.

Condition:

-45℃ (30minutes),

120℃(30minutes),

Switching

time: Less than 5 minutes, 200 cycles.

Schematic Diagram

Block diagram