Applicable to Toshiba 21T01F, 21R01F, 21T01B, 14R01F, 14T01B,

14R01B, 21T01N, 21T01I, 21T01D, 14T01N, 14T01I, 14T01D

Factory Mode

1. Do not attempt

these adjustments in the Video Mode.

2. The Factory Mode adjustments are necessary when either the EEPROM (IC902) or

the CRT is replaced.

3. Do not tamper with the “Adjustment” screen of the Factory Mode menu. This

screen is intended only for factory use.

When EEPROM (IC902) Is Replaced.

1. When IC902 is replaced all adjustment data revert to initial values. It is

necessary to re-program this data.

2. After IC902 is replaced, warm up the TV for 10 seconds.

When CRT Is Replaced.

1. Make the following adjustments AFTER setting up after setting up purity and

convergence:

White Balance

Sub-Brightness

Vertical Center

Vertical Size

Horizontal Size

Fail Safe (This adjustment must be the last step).

2. If the EEPROM or CRT is replaced, set PVA to 40 (factory mode) and set SC as

follows.

14 inch : 18

21 inch : 24

Factory or Service Mode.

Procedure for

the “Adjustment” Mode.

1. This mode uses the standard remote control.

The Service Mode is activated by entering the following remote-control sequence

:

(1) DISPLAY→FACTORY.

(2) STAND-BY→DISPLAY→MENU→MUTE →POWER ON.

2. The “SERVICE (FACTORY)” message will be displayed. The Service Mode has

three components: ADJUST, OPTION and RESET.

3. Access the Adjustment Mode by pressing the “VOLUME” keys ( Up or Down). The

adjustment parameters are listed in the accompanying table, and selected by

pressing the CHANNEL keys (▲ ,▼).

4. Selection

sequences for the all system:

DOWN or UP key:

AGC>SCT>SBT>BLR>BLB>RG>GG>BG> VSL>VS>VA>HS>SC>CDL>STT>AKB>

PDL>NDL>PSR>NSR>VOL>LCO>TXP> MVOL>FMWS>AGCS>OMD>SCL>PWL>

AGN>PEK>ACL>FCO>SCBT>TSC

5. The VOLUME keys increase or decrease the adjustment values (stored in the non-volatile

memory) when Adjustment Mode is cancelled.

6. Cancel the Adjustment Mode by re-pressing the “FACTORY” or “Power OFF” key.

Initial data values

NOTE : PVS, PVA, PHS, parameters must be aligned using the 50Hz vertical-field rates.

Option Bytes

In the Service Mode, various can be selected via the Option Table. Example:

RESET

The Reset Mode is used during factory inspection.

Function Reset:

1. Picture Custom

2. Auto Volume Off

3. Color System Auto (option)

4. Blue Screen Off

5. Volume 10

6. CH. Skip Erased

7. CH. Lock Off

1.Usually, a color

TV needs only slight touchup adjustment upon installation. Check the basic

characteristics such as height, horizontal and vertical sync and focus.

2. The picture should have good black and white details. There should be no

objectionable color shading; if color shading is present, perform the purity

and convergence adjustments described below.

3. Use the specified test equipment or its equivalent.

4. Correct impedance matching is essential.

5. Avoid overload. Excessive signal from a sweep generator might overload the

front-end of the TV. When inserting signal markers, do not allow the marker

generator to distort test results.

6. Connect the TV only to an AC power source with voltage and frequency as

specified on the back cover nameplate.

7. Do not attempt to connect or disconnect any wires while the TV is turned on.

Make sure that the power cord is disconnected before replacing any parts.

Automatic Degaussing.

A degaussing coil is mounted around the picture tube, so that external

degaussing after moving the TV should be unnecessary. But the receiver must be

properly degaussed upon installation.

The degaussing coil operates for about 1 second after the power is switched ON.

If the set has been moved or turned in a different direction, disconnect its AC

power for at least 30 minutes.

If the chassis or parts of the cabinet become magnetized, poor color purity

will result. If this happens, use an external degaussing coil.

Slowly move the degaussing coil around the faceplate of the picture tube and

the sides and front of the receiver. Slowly withdraw the coil to a distance of

about 6 feet before removing power.

High Voltage Check.

CAUTION: There is no high voltage adjustment on this chassis.

The B+ power supply must be set to +125 volts (Full color bar input and normal

picture level).

1. Connect a digital voltmeter to the second anode of the picture tube.

2. Turn on the TV. Set the Brightness and Contrast controls to minimum (zero

beam current).

3. The high voltage should not exceed 27.5KV.

4. Adjust the Brightness and contrast controls to both extremes. Ensure that

the high voltage does not exceed 27.5KV under any conditions.

FOCUS Adjustment.

1. Input a black and white signal.

2. Adjust the tuning control for the clearest picture.

3. Adjust the FOCUS control for well defined scanning lines in the center area

of the screen.

Cathode Voltage Adjustment (Screen Adjustment)

1. Enter the FACTORY mode.

2. Select the G2-ADJUST.

3. Adjust the screen VR(on the FBT) so that ‘SCREEN ADJUST : NG(Red or Blue)’ becomes

‘SCREEN ADJUST : OK’.

When the color of ‘SCREEN ADJUST’ is red, the cathode voltage is low and when

blue, it is high.

4. Input a black

and white signal.

5. Fully demagnetize the receiver by applying an external degaussing coil.

6. Turn the CONTRAST and BRIGHTNESS controls to maximum.

7. Loosen the clamp screw holding the yoke.

Slide the yoke backward or forward to provide vertical green belt.

8. Tighten the convergence yoke.

9. Slowly move the deflection yoke forward, and adjust for the best overall

green screen.

10. Temporarily tighten the deflection yoke.

11. Produce blue and red rasters by adjusting the low-light controls. Check for

good purity in each field.

White Balance Adjustment.

Set up

1. Warm up the TV for at least 30 minutes in the Aging Mode (OSD White). This

mode is entered by entering the following sequence:

(Displaying AGING on the screen)

DISPLAY →FACTORY →FACTORY

2. Input a Toshiba pattern.

(b) Low-Light Adjustment

1. Set SBT to 3.5 ± 0.5 fL in the Factory Service Mode with using CA100.

(14inch : 2.5 ± 0.5fL, 21inch : 1.5 ± 0.5fL)

2. Adjust RG,BG so that the levels are suitable to each local area.

(c) High-Light

Adjustment

1. Set SCT to 35 FL (20”. 21”), 60 FL(14”) in the Factory Service Mode with

using CA100.

Center Convergence Adjustment

1. Warm up the receiver for at least 20 minutes.

2. Adjust the two tabs of the 4 pole magnets to change the angle between them.

Superimpose the red and blue vertical lines in the center area of the screen.

3. Adjust the Brightness and Contrast controls for a well defined picture.

4. Adjust the two-tab pairs of the 4 pole magnets, and change the angle between

them.

Superimpose the red and the blue vertical lines in the center area of the

screen.

5. Turn the both

tabs at the same time, keeping the angle constant, and superimpose the red and

blue horizontal line in the center of the screen.

6. Adjust the two-tab pairs of the 6-pole magnets to superimpose the red and

blue line onto the green. (Changing the angle affects the vertical lines, and

rotating both magnets affects the horizontal lines.)

7. Repeat adjustments 2~6, if necessary.

8. Since the 4-pole magnets and 6-pole magnets interact, the dot movement is

complex

RF AGC Adjustment

Set the AGC data to 33 (Factory Mode).

Sub-Color Adjustment

Set data to (Factory Mode).

Geometry Adjustment

SC →VS→VSL→HS

1. Input a lion head pattern (in the PAL channel).

2. Set the SC (S-Correction) as follows : 24 (21”),

24 (20”), 18 (14”) and VA 40 so that the lion head circle becomes oval.

3. Adjust with VSL (Vertical-Slope) so that the bottom margin of the picture is

4.

4. Adjust with VS (Vertical shift) so that the top margin of the picture is 4.

6. Adjust HS (using the width coil) so that the left and right margins of the picture are 5

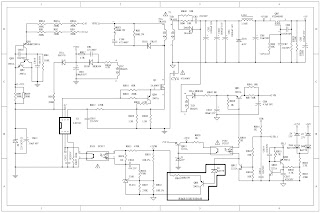

Wiring diagram and schematic diagram